“My graphic design interest began when I was 13. Just for fun, I followed tutorials online and did projects for myself. So in a way, I have accidentally been training myself for an entrepreneurial job since I was just out of my pre-teens. I’m lucky I followed those tutorials and learned the skills when I did. Unfortunately, there aren’t any tutorials online for making custom bathymetric lake depth maps on a laser cutter. I had to figure that out myself, expanding on the skills I learned during the past seven years when I was experimenting with graphic design just for the fun of it.

“My parents, Sally and Daniel Brehm have influenced my life in a positive way as has my girlfriend, Payden Teeple. Outside of woodworking, Dad didn’t have any laser cutting/small business experience. My business, Nautical Woodworks, was primarily influenced by my boss, Matthew Bathey at Superior Pizza & Subs, where I worked as a chef for the past few years. Matt has another business called Superior Steelworks where he utilizes a CNC plasma-cutter which is similar to my machine, but it cuts steel instead of wood. I had the idea of buying a laser cutter simply because I thought they were cool. When I told him about it, he encouraged me to go for it and make a business out of it. So at age 19, I bought the laser cutter and started my business. That was a year ago and I’m glad I did.

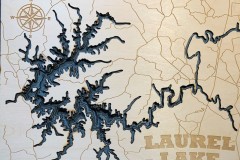

“Everything I’ve made so far has been made with Baltic Birch plywood. The maps have been framed with hardwood, usually cherry. The process of making a map has a few steps. First, I do research online to learn the data of what the depth of it looks like. Then I move my process over to Vector Design Software. I use Adobe Illustrator and begin drawing out the map in separate layers. I also draw out that which gets engraved on the top layer. Then it’s exported into files the laser cutter can read. It’s cut in separate layers and each layer is glued together. When that process is finished, I work on the frame. I sand and color the wood with an oil based stain. Once the piece is completely done, it’s given a few coats of semi-gloss lacquer. This doesn’t change the color much, but it does give it a nice finish and protects the wood.

“My father helps make the frames. He’s retired now and has more time to do woodworking, something he’s always loved, although, instead of dedicating himself completely to his craft, he’s stuck making frames for me. Fear not. I don’t overload him, and I pay him well for his time. I’ve told him I’ll take over making the frames if he gets tired of it. The last thing I want to do is exploit my Dad. This arrangement has enabled us to spend more time together. Our relationship extends far beyond business, and he hasn’t complained about helping me. I’m incredibly lucky to have him.

“My main theme is lakes, and I suppose that’s no surprise. Being raised in Northern Michigan, lakes are important to me. I enjoy my work and have a talent for it. Besides the maps, I’ve engraved cutting boards, made necklaces, key chains, and ornaments. Ultimately, I think the lake maps are my favorite product and where I receive the greatest fulfillment. It brings me a lot of joy to think I’m creating a unique piece of art for customers. It’s something they can’t get elsewhere. At least, not exactly like mine.

“Readers might be interested in my first order. As I mentioned, my boss encouraged me to buy the laser cutter. Once purchased, it took a week to arrive. He knew the day it was coming and sent a text asking if it was here yet. I said I was in the process of unpacking it. At the same time he was reading my text, he got a call from a friend, and here’s the great part. The friend wanted to know if Matt knew anyone with a laser cutter. Obviously, he did. Even before the laser was unpacked, the caller, Ken Hopper, placed an order. He needed engraving done on 200 participation wooden disk trophies as well as several other trophies for the 7Bridges 7Brews, a 5k and 10k fun run orchestrated through his company, Bird’s Eye Outfitters in Sault Ste. Marie, Michigan. The kicker was I got the machine on a Monday, and he needed the disks completed by Thursday. I hadn’t even plugged the machine in yet. I spent the next few hours familiarizing myself with it while also making a quick mock up of what they wanted. I met with Hopper later that very evening, and he gave me the disks intended to be engraved. In reality, I had no idea if it was going to be possible, but I said I could do it. After a few back-to-back long nights, I managed to successfully complete the order within the timeframe, and the runners had their trophies. Call it a trial by fire.

“At this point in my life, I’m not really sure what my future plans are for the business. I enjoy doing laser engraving, but my ultimate dreams extend beyond Nautical Woodworks. The lessons and skills I learn from this are what are most important to me. If I can make a few dollars along the way, that’s cool, but at this point the experience I’m gaining from the work and connecting with others is invaluable. If anything, the biggest lesson thus far has been in creating the business. I thought to myself a year ago, ‘Wouldn’t it be crazy if I did this?’ I am doing it, and it is amazing!”

In addition to his laser business, Cole is a mentor to the Brimley High School robotics team that recently returned from Houston where the global championships were held and where they competed. As Cole said, “It was a blast!” He can be reached at woodworksnautical@gmail.com. To learn more about his laser business, check out his Facebook and Esty pages at http://www.facebook.com/nauticalww and https://www.etsy.com/shop/NauticalWoodworksArt.

click on thumbnail to enlarge photo…

- Saying Goodbye to Charlie Brown - July 2, 2024

- Mike Lynn Says Farewell to Lynn Auto Parts, Inc. - November 25, 2022

- Sharon Kennedy:The Hay Fields of Tony Jarvie - August 11, 2022